Company Profile

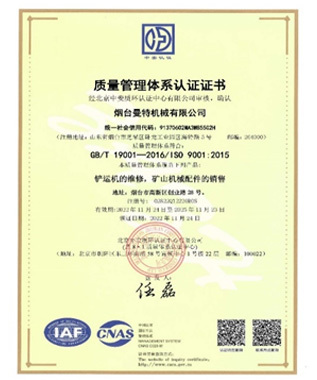

Yantai Mante Machinery Co., Ltd. was established in 2018 and is located in Yantai, Shandong Province. It specializes in the design, research and production of trackless equipment for mines, as well as the maintenance of spare parts and major repairs for trackless equipment (mainly including well-known domestic and foreign brands such as Nanchang Kaima, Xingye, Beijing Anqisheng, Qingdao Zhonghong, Anbaituo, XCMG, Tongguan, China Steel, Derui, Shantevik, etc.), And has obtained the ISO-9001 quality management system certification, equipped with a factory building of over 5000 square meters, and a warehouse of 3000 square meters of mining equipment spare parts and accessories, with sufficient supply of spare parts. Yantai Mante Machinery Co., Ltd. is also continuously improving and providing technical training in the production, manufacturing, and maintenance services process, making Yantai Mante Machinery's services more in line with customer interests, and striving to shape a reliable brand image in the industry, To achieve reliable quality and first-class service, adhering to the corporate vision of becoming the most trusted partner in the industry, the company has been continuously optimizing and improving its industrial model since its establishment, making every effort to meet customer needs, helping customers create value better, produce efficiently, and enhance the company's competitiveness.

In terms of talent allocation, Yantai Mante Machinery currently has 24 professional equipment engineers, all of whom are professionals in mechanical, hydraulic, and electrical fields. They have served the mining industry for more than ten years and have rich experience in production and manufacturing, as well as maintenance capabilities. They have all received professional training, and have a precise understanding of various products and systems of trackless mining equipment. They are able to provide scraper training to customers, Can quickly and accurately analyze and diagnose product faults and handle them. Yantai Mante Machinery Co., Ltd. arranges technical and maintenance personnel to visit Volvo, Mercedes Benz, and Dena factories for technical learning every year, and requires suppliers such as Kessler, Deutz, and Cummins to come to our company multiple times for technical training. We have a clear understanding of equipment malfunctions and potential issues, and can provide direct answers or on-site services to customer inquiries. Our staff are on standby 24 hours a day to understand customer needs as soon as possible and solve customer problems in the shortest possible time.

In terms of equipment configuration, Yantai Mante Machinery Co., Ltd. has a major repair workshop with test benches for gearboxes, torque converters, drive axles, and hydraulic cylinders. We specialize in the assembly and major repair of these assemblies. Our company has a comprehensive maintenance process and quality management system to ensure that every link is controllable and strictly controlled. Yantai Mante Machinery Co., Ltd. always believes that science is the primary productivity and improves work efficiency, To reduce error rates, the company has been continuously investing in maintenance equipment since its establishment, introducing high-tech equipment, and striving to become a benchmark enterprise in the maintenance industry, so as to continuously improve our maintenance quality and ensure the stable and reliable quality of factory accessories and maintenance services.

In terms of component selection, Yantai Mante Machinery Co., Ltd. purchases advanced products in the industry, always putting product quality first, controlling the source through inspection and handling, strictly controlling the process, and ensuring product quality through warehousing. Summarize and report any non-conforming items discovered through supplier self inspection and inspector re inspection. Improve acceptance criteria: Develop acceptance criteria for hydraulic, transmission, power, structural and other components, improve the sampling rate of purchased pump, valve, and motor components, and effectively reduce the possibility of product quality issues.

In terms of sales, Yantai Mante Machinery Co., Ltd. does not have a large sales team. With our reliable product quality and comprehensive after-sales service system, our sales performance has shown a geometric growth. The growth of performance mainly relies on the trust of customers, which enables us to cooperate with enterprises for a long time. Our brand reputation in the industry continues to improve.

In terms of after-sales service, our company can provide on-site replacement parts service for customers. For on-site equipment maintenance or parts with high replacement frequency, our company conducts maintenance and testing on site to modify and improve unreasonable items, reduce customer failure rates and maintenance costs. After one week of product delivery, our company's after-sales service department personnel will follow up with customers by phone based on their contact information. After three months of product use, we will provide a telephone follow-up service to gain a detailed understanding of your company's usage situation. We will improve our cooperation and supply in the future. If there are quality problems or non human damage during the warranty period, our company is obligated to provide free repair, return, and exchange. If our employees cannot solve the problem over the phone, our company's maintenance personnel will come to the purchaser's site within 8 hours to solve the problem.

Mante Machinery

Contact person: Mr. Sui

Tel: 086-13863833991

Email: yantaimante@163.com

Add: No. 28 Chuangye Road, Gaoxin District, Yantai City, Shandong Province

Copyright © Mante Machinery

右侧在线客服组件

SAF Coolest v1.2 设置面板 SWHSX-ZXOZ-JXZVE-ZWS

无数据提示

Sorry, there is currently no content in the current column!

You can view other columns or return to HOME